Struggling to navigate tight corners or create custom pipe configurations? Rigid PVC fittings force you into standard angles, waste materials, and create weak points with multiple joints. Without knowing proper bending techniques, you’ll crack expensive pipes, create kinks that restrict flow, or compromise structural integrity. This expert guide reveals five professional PVC pipe bending methods that deliver smooth, durable curves for any project.

Bending PVC pipes offers significant advantages over traditional fitting assemblies in many applications. Understanding when to bend versus when to use fittings helps optimize your plumbing and construction projects.

Fewer Leak Points: Every fitting joint represents a potential failure point. Bent pipes eliminate unnecessary connections, reducing leak risks by up to 60% in complex installations. A single smooth bend replaces two elbows and a coupling, removing three potential leak sources.

Smoother Flow Characteristics: Sharp elbow fittings create turbulence and reduce flow efficiency. Gradual bends maintain laminar flow, reducing pressure drops and improving system performance. This becomes critical in high-flow applications like pool circulation or irrigation systems.

Cost Savings: Quality PVC fittings add up quickly. A simple 90-degree configuration using two elbows costs more than heating and bending a single pipe section. Large projects save hundreds of dollars through strategic bending.

Cleaner Aesthetics: Bent pipes create sleek, professional-looking installations without the bulky appearance of multiple fittings. This matters in visible applications like exposed plumbing or artistic projects.

Custom Angles: Standard fittings come in fixed angles—typically 22.5°, 45°, and 90°. Bending allows any angle between 0° and 90°, perfect for navigating irregular spaces or matching existing structures.

Despite bending advantages, fittings remain the better choice for:

Understanding how to glue PVC pipe properly becomes essential when fittings are necessary for your project.

Successful PVC bending requires understanding the material’s thermal and physical properties. PVC (Polyvinyl Chloride) behaves predictably when heated, but different schedules and formulations respond differently.

Glass Transition Temperature: PVC becomes pliable at approximately 176°F (80°C). Below this temperature, the material remains rigid. Above it, PVC softens progressively until reaching full plasticity around 212-250°F (100-121°C).

Melting Point: Pure PVC doesn’t have a sharp melting point but degrades around 500°F (260°C). Overheating releases toxic chlorine gas and permanently damages the pipe structure.

Thermal Expansion: PVC expands approximately 0.00034 inches per inch per degree Fahrenheit. This expansion must be considered when heating pipes, as rapid temperature changes cause stress.

Different PVC pipe schedules affect bending difficulty:

Schedule 40: The most common and easiest to bend. Thinner walls heat faster and require less force for shaping. Ideal for residential applications and DIY projects.

Schedule 80: Thicker walls resist bending and require higher temperatures or longer heating times. Better for applications requiring extra strength after bending.

Pipe diameter significantly impacts bending difficulty:

Smaller diameter pipes bend more easily but also kink more readily without proper technique.

PVC bending involves high temperatures and potential hazards. Proper safety measures prevent injuries and property damage.

Heat-Resistant Gloves: Never handle heated PVC with bare hands. Quality welding gloves or heat-resistant work gloves rated to at least 400°F protect against burns.

Safety Glasses: Heated PVC occasionally releases moisture or contaminants that can splatter. Eye protection is mandatory.

Respiratory Protection: When heating PVC above 350°F, wear an N95 mask or respirator. Overheated PVC releases hydrogen chloride gas, which is harmful when inhaled.

Ventilation: Always work in well-ventilated areas. Open windows, use fans, or work outdoors when possible. Never heat PVC in enclosed spaces without proper ventilation.

Fire Prevention:

Environmental Considerations:

Use an infrared thermometer to monitor pipe temperature. Optimal bending temperature ranges from 200-250°F. Temperatures exceeding 350°F risk material degradation and toxic fume release.

The heat gun method offers the most control and precision for PVC bending. Professional plumbers prefer this technique for its consistency and versatility.

Preparation Phase:

Heating Process:

Bending Execution:

Cooling and Finishing:

The hot water bath method provides uniform heating for simpler bends, making it ideal for beginners or when working with smaller diameter pipes.

Setup Phase:

Heating Process:

Bending Execution:

Advantages of Hot Water Method:

Limitations:

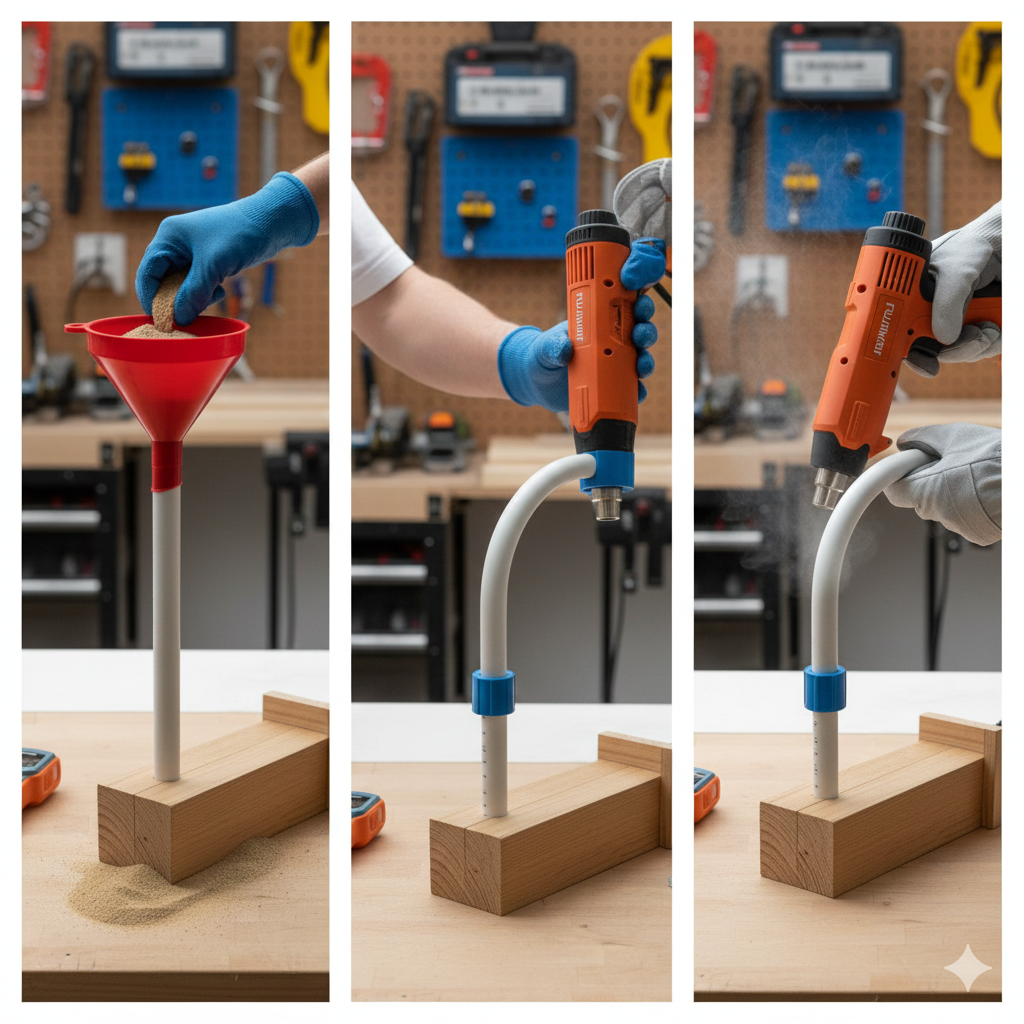

The sand-filled technique prevents pipe collapse during bending, producing perfectly round curves without flattening or kinking. This method works exceptionally well for larger diameter pipes.

Preparation:

Heating and Bending:

Sand Removal:

The oven method provides controlled, even heating for multiple pipes or complex bending projects requiring consistency.

Safety Warning: Never use a food-preparation oven for PVC heating. Dedicate a separate appliance or use an industrial oven. PVC releases chemicals when heated that contaminate surfaces.

Setup:

Heating Process:

Bending:

The hair dryer method suits small-diameter pipes (1/2″ to 1″) and minor bends where high temperatures aren’t necessary.

Setup and Heating:

Bending:

Understanding common errors helps you achieve professional results on your first attempt.

Problem: Heating PVC beyond 350°F causes material degradation, discoloration, and structural weakness. Overheated PVC turns brown or yellow and becomes brittle.

Solution: Use an infrared thermometer to monitor temperature constantly. Maintain working temperature between 200-250°F. Move heat sources continuously to prevent hot spots.

Problem: Heating only one side creates irregular bends, weak spots, and potential failure points. The heated side compresses while the cool side remains rigid, producing oval cross-sections.

Solution: Rotate pipes continuously during heating. Heat guns should move in consistent patterns around the entire circumference. Water bath methods naturally provide even heating.

Problem: Forcing cold or insufficiently heated PVC creates stress fractures, kinks, and permanent damage. Quick bends flatten pipe cross-sections, reducing flow capacity.

Solution: Allow adequate heating time for your pipe size. Test flexibility before applying significant pressure. Work gradually, especially on tight radius bends.

Problem: Removing pipes from jigs too quickly allows partial spring-back, losing your desired angle. Hot PVC lacks structural rigidity.

Solution: Maintain pressure for minimum 30 seconds initial cooling. Keep pipes in jigs for 3-5 minutes before release. Allow complete cooling before subjecting to stress.

Problem: Bending large diameter or thin-wall pipes without internal support causes collapse and oval distortion.

Solution: Use the sand-filling method for pipes larger than 2 inches or when creating tight radius bends. Internal support maintains round cross-sections.

Problem: Different PVC pipe types require different heating approaches. CPVC requires higher temperatures than standard PVC. Understanding material differences prevents damage.

Solution: Verify pipe material before beginning. Standard PVC softens at lower temperatures than CPVC. Adjust heating time and temperature accordingly.

Professional plumbers use these techniques to achieve consistent, high-quality bends.

Build reusable templates for common angles and radii:

Templates ensure repeatability across multiple projects and reduce setup time.

Master techniques risk-free:

Clear marking improves accuracy:

Position work to use gravity assistance:

Strategic cooling improves results:

Understanding how to pressure test PVC pipe becomes crucial after bending. Bent sections should maintain original pressure ratings when properly executed.

Post-Bend Testing Protocol:

Properly bent PVC pipes require minimal maintenance but benefit from periodic inspection.

Visual Checks (Annually):

Pressure System Checks:

Outdoor Installation Considerations:

PVC degrades under prolonged UV exposure. Bends experience more stress than straight sections, making protection essential for longevity.

Proper Support:

Thermal Effects on Bent Pipes:

Replacement Indicators:

Learn how to cut PVC pipe properly when replacement becomes necessary.

Yes, most PVC formulations can be bent with proper heating techniques. Standard Schedule 40 and Schedule 80 PVC bend successfully at 200-250°F. However, some specialty PVC formulations like cellular core or foam core pipes don’t bend well due to internal structure. CPVC requires higher temperatures (around 280°F) than standard PVC. Always verify your specific pipe material before attempting to bend.

Minimum bend radius depends on pipe diameter and wall thickness. A general rule suggests minimum radius of 3-4 times the pipe’s outside diameter for Schedule 40, and 4-5 times for Schedule 80. For example, a 2-inch Schedule 40 pipe (2.375″ OD) should maintain a minimum 7-10 inch radius. Tighter bends risk kinking, flattening, or creating stress points that fail under pressure.

Properly executed bends maintain approximately 90-95% of the original pressure rating when the radius exceeds minimum recommendations and the pipe doesn’t show stress whitening or deformation. Poorly executed bends with flattened cross-sections, kinks, or visible stress marks significantly reduce pressure capacity—sometimes by 50% or more. Always pressure test bent sections before installing in critical applications.

Bent PVC reaches handling strength within 5-10 minutes of cooling to room temperature. However, the molecular structure continues stabilizing for 24-48 hours. For best results, allow bent pipes to rest for at least 24 hours before subjecting them to pressure or stress. Critical applications benefit from 48-72 hours of curing time before pressure testing or installation.

Yes, PVC can be reheated and rebent multiple times, though each heating cycle slightly degrades the material. Limit reheating to 2-3 times maximum on the same section. Each bend-reheat cycle increases brittleness and reduces long-term durability. If possible, cut out poorly bent sections and start with fresh pipe for critical applications requiring maximum strength and longevity.

Temperatures exceeding 350°F cause irreversible damage to PVC structure. At 400°F and above, PVC begins releasing toxic chlorine gas and degrading rapidly. Optimal bending temperature ranges from 200-250°F for standard PVC. Use infrared thermometers to monitor temperature precisely. Discoloration (yellowing or browning) indicates overheating—discard overheated sections as they’ve lost structural integrity.

No special sealing is required for bent PVC sections. Standard PVC primer and cement work identically on bent and straight sections when following proper gluing techniques. Ensure surfaces are clean, apply primer thoroughly, and use appropriate cement for your pipe schedule. The bending process doesn’t affect the chemical bonding process used in PVC connections

Kinking prevention requires three key techniques: gradual heating with constant rotation ensures even temperature distribution, filling pipes with dry sand provides internal support preventing collapse, and using larger radius bends (4-5x pipe diameter) reduces stress concentration. Work slowly, applying gentle pressure as the pipe softens rather than forcing quick bends on insufficiently heated material.

Absolutely. Properly bent PVC pipes perform excellently in pressurized water systems when executed correctly. The bend must maintain round cross-section without flattening, show no stress whitening or discoloration, use adequate bend radius (3-4x pipe diameter minimum), and pass pressure testing at 1.5x working pressure. Many professional installations use bent PVC successfully in irrigation, pool plumbing, and water distribution systems.

For pipes 3 inches and larger, the sand-filling method combined with heat gun application produces best results. Fill pipe completely with dry sand to prevent collapse, heat gradually while rotating continuously, use commercial or custom-made forming jigs for consistent radius, and allow extended heating time (proportional to wall thickness and diameter). Large pipes require patience—rushing large diameter bends almost always produces poor results with flattening or irregular curves.

Properly heated PVC exhibits specific signs: surface temperature reads 220-250°F on infrared thermometer, pipe feels uniformly warm when touched with gloved hand, gentle pressure causes the pipe to flex smoothly without resistance, and the pipe maintains slight flexibility without being overly soft. If the pipe feels rigid, continue heating. If it becomes too soft and loses shape, reduce temperature slightly.

Most PVC pipe manufacturers design their products for potential bending applications and don’t automatically void warranties. However, warranties typically exclude damage from improper installation techniques including overheating, excessive stress, or inappropriate applications. Document your bending process with temperature logs and pressure tests for critical installations. For commercial projects, consult manufacturer specifications or contact technical support before bending.

Mastering PVC pipe bending opens new possibilities for custom plumbing, irrigation, and construction projects. This comprehensive guide has equipped you with five proven methods—from beginner-friendly hot water techniques to professional heat gun applications.

Remember that successful PVC bending requires patience, proper temperature control, and attention to detail. Whether you choose the precision of heat gun bending, the simplicity of hot water methods, or the kink-prevention benefits of sand-filling, each technique delivers professional results when executed correctly.

Ready to start your PVC pipe bending project? Visit Dave Pools for quality Schedule 40 and Schedule 80 PVC pipes, professional fittings, heat-resistant tools, and expert guidance. Our comprehensive selection and technical support ensure you have everything needed to achieve perfect bends with professional results that last for decades.