Are you planning a plumbing installation and wondering whether PPR pipe is compatible with hot or cold water? This is a critical question that impacts not only the immediate success of your plumbing project but also its long-term durability, safety, and efficiency. In today’s modern plumbing systems, material selection can make or break your installation.

The wrong choice of piping material can lead to costly repairs, potential health hazards, and inefficient systems that waste energy and money. With the variety of options available in the market today—from traditional copper and galvanized steel to newer materials like PVC, CPVC, PEX, and PPR—making an informed decision has never been more important.

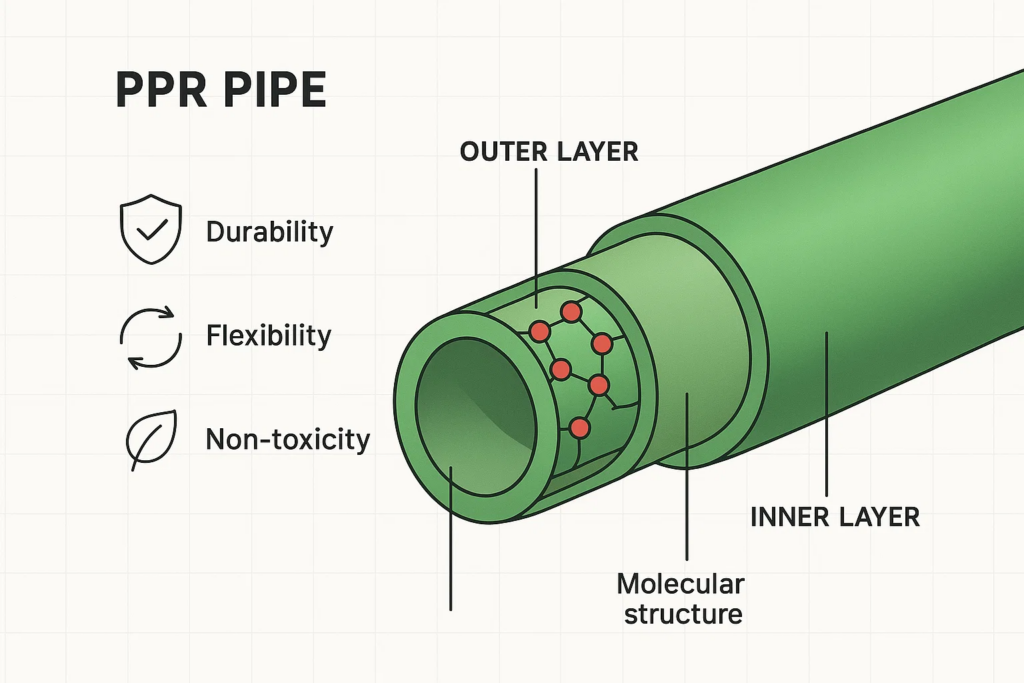

Polypropylene Random Copolymer (PPR) pipe is an advanced thermoplastic piping system that has revolutionized modern plumbing installations. Unlike conventional piping materials, PPR is manufactured through a specialized polymerization process that combines propylene monomers in a random configuration, creating a material with exceptional physical and chemical properties.

PPR pipe has gained significant popularity in residential, commercial, and industrial applications due to its unique combination of flexibility, durability, and resistance to various environmental factors. The material is non-toxic, environmentally friendly, and doesn’t leach harmful chemicals into water, making it an excellent choice for potable water systems.

PPR pipes are typically green in color (though other colors are available for specific applications) and connected using thermal fusion welding—a process that creates seamless, leak-proof joints that are often stronger than the pipe itself. This fusion process eliminates the need for solvent cements, glues, or mechanical fittings that can deteriorate over time and become potential failure points.

The various types of PPR pipe fittings available in the market allow for versatile installation configurations to meet virtually any plumbing requirement.

One of PPR pipe’s most significant advantages is its exceptional compatibility with hot water systems. Unlike many other plastic piping materials that degrade or deform under high temperatures, PPR is specifically engineered to handle hot water applications with ease.

PPR pipes can safely transport water at temperatures up to 95°C (203°F) under normal operating conditions, making them ideal for:

The material’s molecular structure provides remarkable thermal stability, allowing it to maintain its structural integrity and mechanical properties even when exposed to hot water over extended periods. This resistance to thermal degradation ensures a longer service life compared to many alternative materials.

Additionally, PPR’s thermal fusion joining method creates homogeneous connections that are equally resistant to hot water, eliminating the risk of joint failures common in systems using mechanical connections or adhesives that can break down under heat.

Many property owners are now choosing PPR pipe for hot water supply due to these advantages, particularly in applications where temperature fluctuations are frequent.

While PPR pipe excels in hot water applications, it’s equally effective for cold water systems. In fact, its performance characteristics make it an excellent all-around solution for comprehensive plumbing installations.

For cold water applications, PPR offers several advantages:

When comparing PPR pipe to PVC pipe, many professionals prefer PPR for combined hot and cold water systems due to its versatility, while PVC is typically limited to cold water applications only.

A common question among homeowners and contractors is: “What’s the difference between PPR pipe hot and cold water pipes?” The answer lies not in the base material but in the specific formulation and pressure ratings.

PPR pipes for both hot and cold water applications are made from the same basic material—polypropylene random copolymer. However, there are several important distinctions:

It’s important to note that while these differences exist, a properly specified PPR pipe system can usually handle both hot and cold water, with the specifications determined by the most demanding conditions the pipe will experience.

Understanding the difference between PN10 and PN16 pressure ratings is crucial when selecting the appropriate PPR pipe for your specific application.

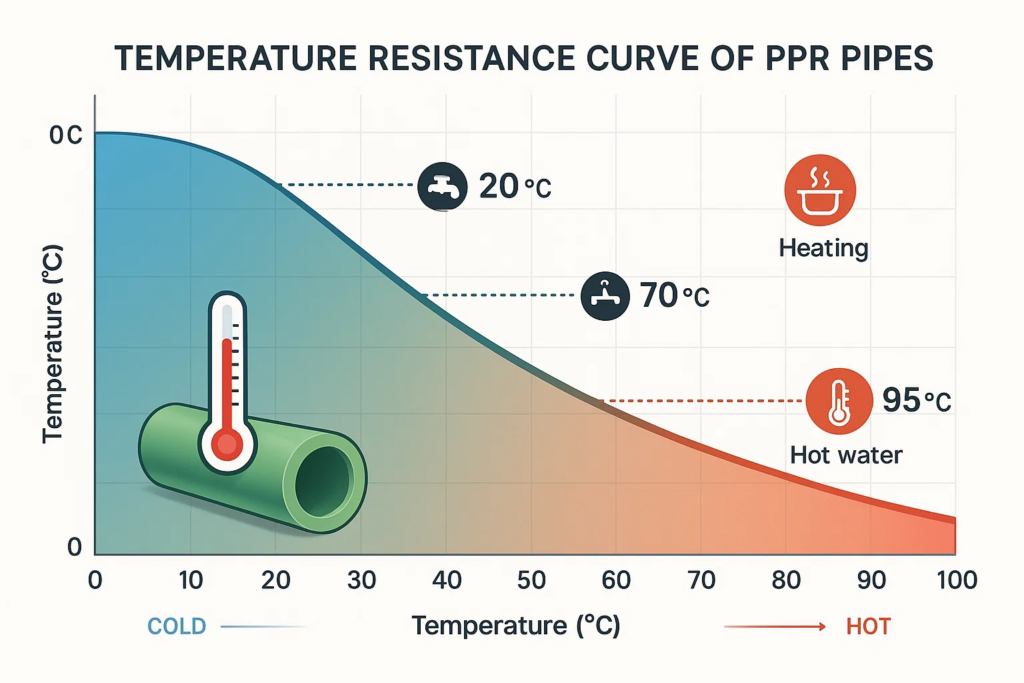

The temperature resistance of PPR pipes is one of their most remarkable characteristics and a primary reason for their widespread adoption in modern plumbing systems.

PPR pipes can handle a continuous operating temperature of up to 70°C (158°F) and can withstand short-term exposure to temperatures as high as 95°C (203°F). This exceptional thermal stability is due to the material’s molecular structure, which provides:

The temperature performance of PPR is classified according to international standards, typically following ISO 15874, which defines application classes for different temperature profiles:

Each class specifies the temperature conditions the pipe must withstand for a designated service life (typically 50 years). PPR pipes are commonly certified for Classes 1, 2, and sometimes 4, depending on their specific formulation and pressure rating.

Pressure ratings are a crucial consideration when selecting PPR pipes for hot or cold water applications. These ratings, typically expressed as PN (Pressure Nominal) values, indicate the maximum pressure the pipe can safely handle at 20°C (68°F).

Common pressure ratings for PPR pipes include:

It’s essential to understand that these pressure ratings decrease as temperature increases. For example, a PN20 pipe rated for 20 bar at 20°C might only be rated for 10 bar at 70°C. This relationship between temperature and pressure capacity follows a standardized regression curve defined in international standards.

When designing a plumbing system, engineers must consider:

For most residential hot water applications, PN20 or PN25 pipes are recommended to ensure adequate pressure capacity at elevated temperatures. For cold water systems, PN16 may be sufficient depending on the system pressure.

When deciding on the best pipe for home plumbing, it’s valuable to compare PPR with other common materials to understand its relative advantages and limitations:

| Material | Hot Water Compatibility | Cold Water Compatibility | Lifespan | Installation Method | Cost |

|---|---|---|---|---|---|

| PPR | Excellent (up to 95°C) | Excellent | 50+ years | Heat fusion | Moderate |

| Copper | Excellent | Excellent | 50+ years | Soldering/Crimping | High |

| PEX | Good (up to 82°C) | Excellent | 40+ years | Crimping/Expansion | Moderate |

| CPVC | Good (up to 82°C) | Excellent | 30+ years | Solvent welding | Moderate-Low |

| PVC | Poor (not recommended above 60°C) | Excellent | 30+ years | Solvent welding | Low |

| Galvanized Steel | Moderate | Good | 20-50 years | Threading | Moderate-High |

Compared to metal pipes, PPR offers:

Compared to other plastics, PPR offers:

The choice ultimately depends on specific project requirements, budget constraints, and installer expertise. For comprehensive hot and cold water systems, PPR represents an excellent balance of performance, durability, and cost.

Installing PPR pipe systems for hot and cold water applications requires specific techniques and considerations to ensure optimal performance:

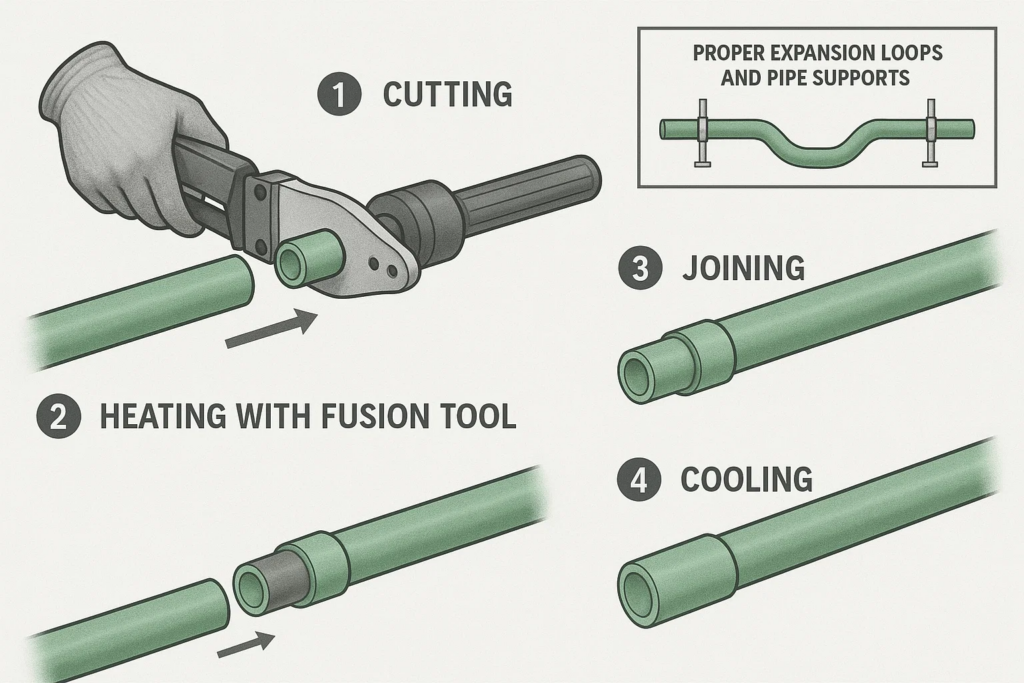

Unlike other piping systems that use mechanical connections or adhesives, PPR pipes are joined through thermal fusion welding, creating molecularly bonded connections. This process involves:

This fusion process creates homogeneous joints that are stronger than the pipe itself and eliminates potential leak points.

PPR pipes, like all thermoplastics, expand and contract with temperature changes. For hot water applications, this thermal expansion must be properly accommodated:

Failure to account for thermal expansion can result in stress on fittings, noisy operation, or even pipe failure over time.

Properly insulating PPR pipes offers several benefits:

The thickness and type of insulation should be selected based on local building codes, environmental conditions, and efficiency goals.

When connecting PPR systems to existing plumbing or fixtures made from different materials, special transition fittings are required:

These transition points deserve special attention during installation as they can be potential weak points if not properly executed.

The long-term performance of PPR pipe systems is one of their most compelling advantages. When properly installed and operated within design parameters, PPR pipes offer exceptional durability:

Quality PPR pipe systems are designed to last a minimum of 50 years under normal operating conditions. This impressive service life is due to several factors:

One of the most significant advantages of PPR systems is their minimal maintenance requirements:

This low maintenance profile translates to significant cost savings over the system’s lifetime, offsetting the initial installation investment.

While PPR is highly durable, certain factors can affect its long-term performance:

By avoiding these conditions and following manufacturer guidelines, PPR systems consistently deliver their full expected service life.

When evaluating whether to invest in PPR pipe systems for hot and cold water applications, consider both initial and lifecycle costs:

PPR systems typically represent a moderate initial investment:

For a typical residential installation, PPR systems often cost 20-30% more than basic PVC systems but 15-25% less than premium copper installations.

The true value of PPR becomes apparent when considering total lifecycle costs:

When these factors are considered, PPR systems often represent the lowest total cost of ownership despite a moderate initial investment. For properties expected to be held long-term, the economic advantages become increasingly significant.

For most installations, the premium cost of PPR versus basic systems is typically recovered within 7-10 years through reduced energy, maintenance, and repair expenses. This makes PPR an especially attractive option for:

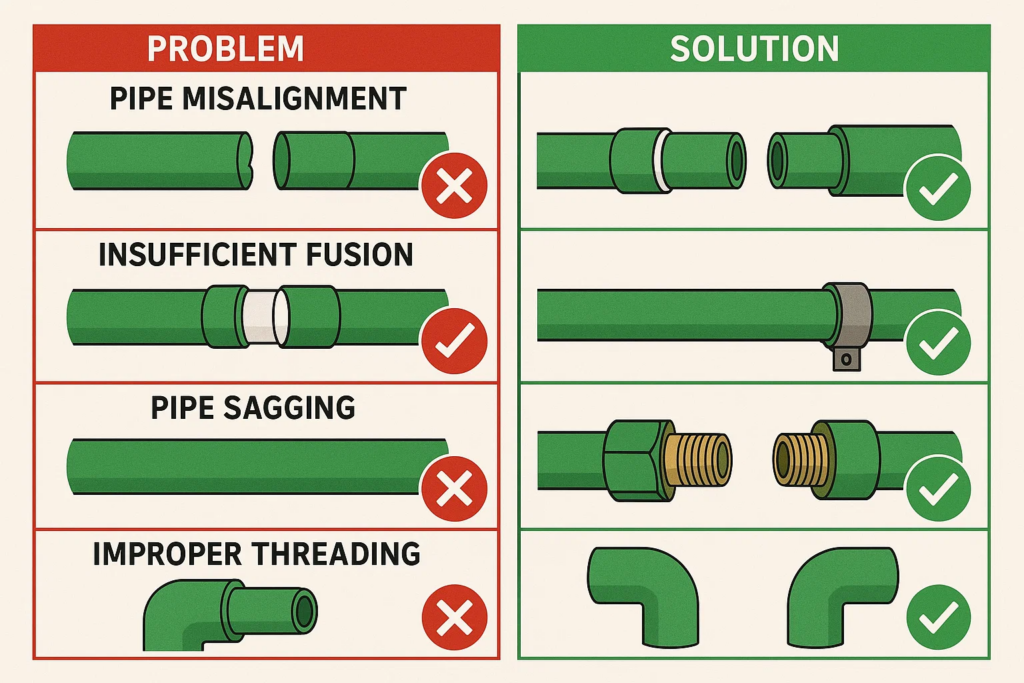

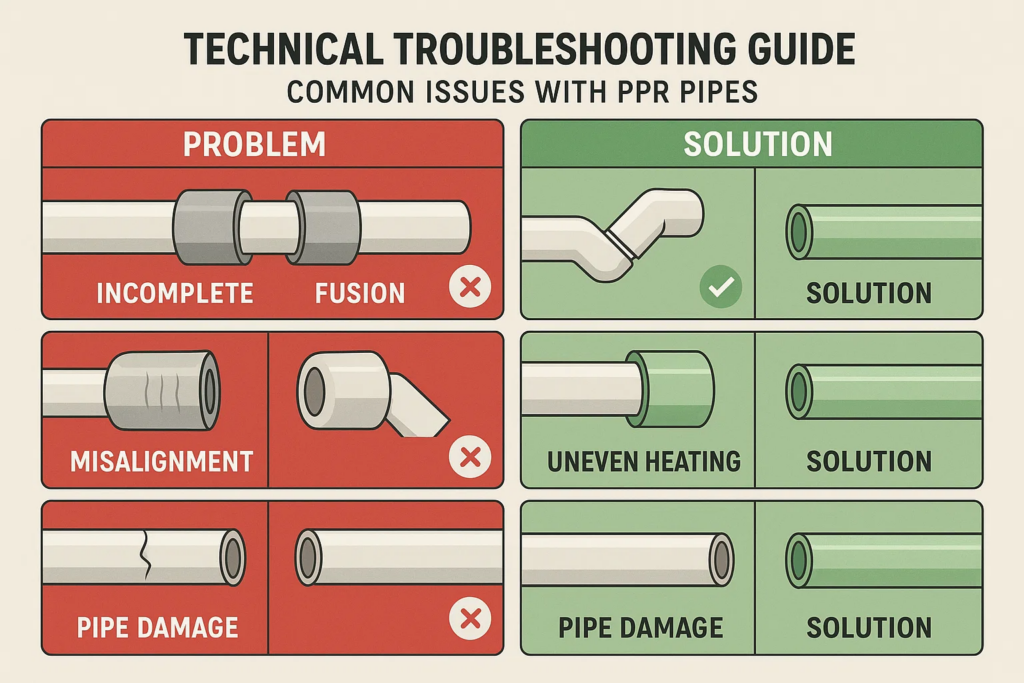

While PPR pipe systems are highly reliable, understanding potential issues and their solutions can help ensure trouble-free operation:

Problem: Leaking or weak connections due to improper heating time, temperature, or insertion depth during fusion welding.

Solution:

Problem: Pipe movement, noise, or stress on fittings due to thermal expansion, particularly in hot water lines.

Solution:

Problem: System failure due to using pipes with inadequate pressure ratings for the application.

Solution:

Problem: Material deterioration when PPR is exposed to direct sunlight for extended periods.

Solution:

Problem: Pressure spikes caused by sudden valve closures can damage PPR systems over time.

Solution:

Addressing these potential issues proactively can significantly extend system life and maintain optimal performance.

The question “Is PPR pipe compatible with hot or cold water?” has a clear answer: PPR is not only compatible with both hot and cold water applications but excels in these environments, offering advantages over many traditional piping materials.

PPR pipe systems represent a modern solution to the age-old challenges of water distribution, providing exceptional durability, safety, and efficiency. Their unique combination of temperature resistance, pressure capacity, and joint integrity makes them ideal for comprehensive plumbing installations.

For homeowners and building professionals seeking a reliable, long-term solution for their plumbing needs, PPR offers compelling benefits:

As building technologies continue to evolve, PPR pipe systems have established themselves as a preferred choice for forward-thinking installations that prioritize performance, sustainability, and long-term value.

Whether you’re planning a new construction project or upgrading existing plumbing, PPR pipes deserve serious consideration for your hot and cold water distribution needs. With proper selection, installation, and minimal maintenance, these systems will provide reliable service for decades to come.

Looking for Quality PPR Pipes and Fitting Supplier in Dubai?

Yes, PPR pipes can be used for both hot and cold water in the same plumbing system. In fact, this is one of PPR’s major advantages—its versatility allows for a unified piping solution throughout a building. Just ensure you select PPR with appropriate pressure ratings (typically PN20 or higher) to handle the highest temperatures the system will experience.

Standard PPR pipes can handle continuous operating temperatures up to 70°C (158°F) and short-term exposure to temperatures as high as 95°C (203°F). For specialized high-temperature applications, reinforced composite PPR pipes can handle even higher temperatures.

Both PPR and copper have advantages for hot water systems. PPR offers better thermal insulation, lower cost, corrosion resistance, and quieter operation. Copper has a longer track record, higher temperature resistance, and better compatibility with existing systems. For new installations, many professionals prefer PPR for its overall performance and value.

The installation process is identical for both hot and cold water PPR pipes, using thermal fusion welding. The key differences lie in system design: hot water systems require more attention to thermal expansion, may use thicker-walled or fiber-reinforced pipes, and typically need insulation for energy efficiency.

Yes, like all thermoplastics, PPR expands slightly when heated. However, PPR has one of the lowest thermal expansion coefficients among plastic piping materials. Proper installation techniques include expansion loops or joints to accommodate this movement without stressing connections.

Quality PPR pipe systems are designed to last at least 50 years in hot water applications when installed correctly and operated within their temperature and pressure ratings. Some manufacturers claim service lives of 70+ years under optimal conditions.

PPR pipes use the same type of fittings for both hot and cold water applications. The fittings are made from the same PPR material as the pipes and are connected using thermal fusion welding, creating a homogeneous system with consistent properties throughout.

Yes, PPR pipe is completely safe for drinking water. It is non-toxic, does not leach chemicals into water, and meets international standards for potable water systems. PPR is tasteless and odorless, ensuring water quality remains unaffected.